SOLUTIONS FOR LOW EMISSIONS OPERATIONS

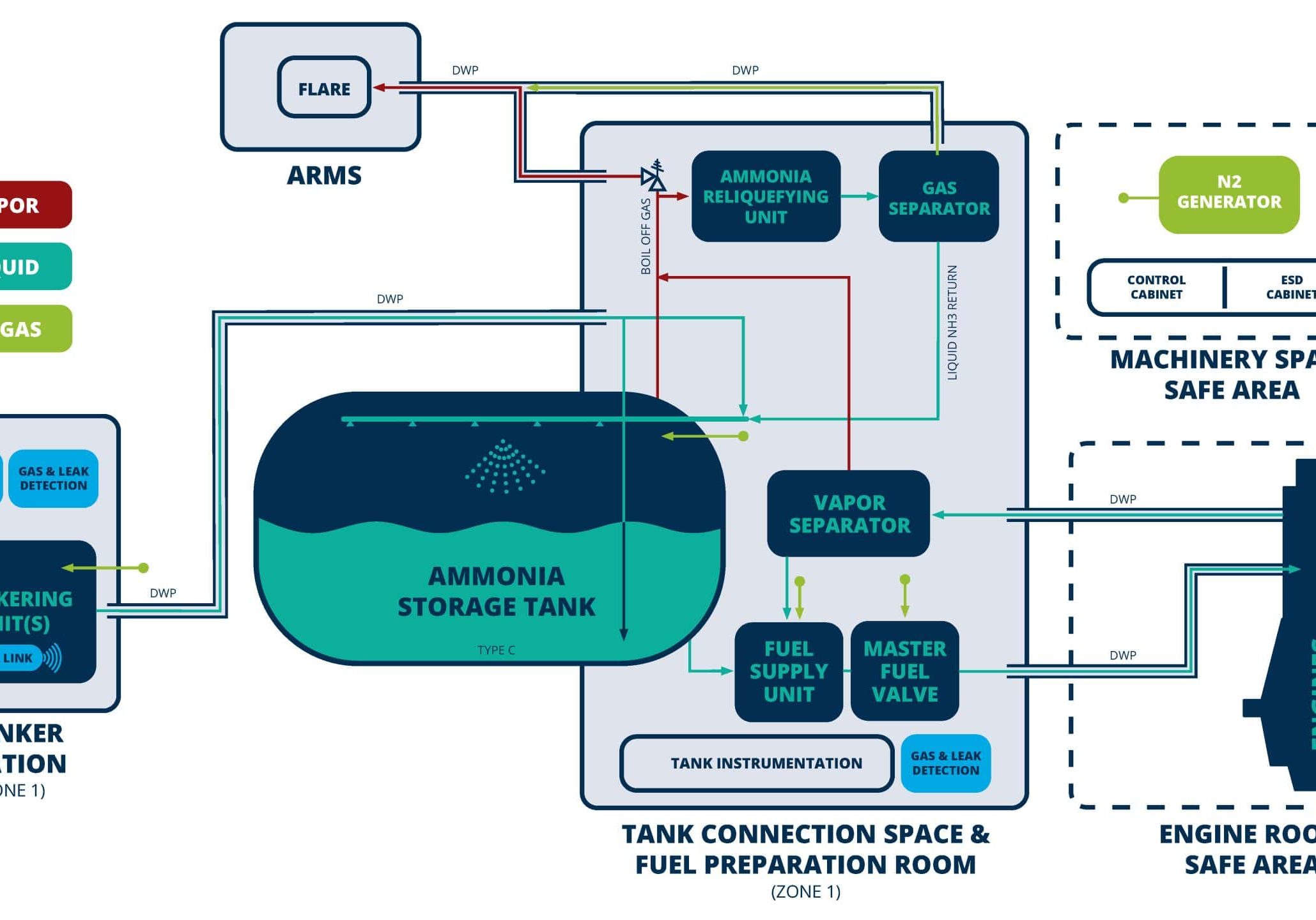

It is likely that the fuel supply system originally designed for your existing ship's main and auxiliary engines was created to run on fuels with differing properties than the future fuels available on the marine market today. New fuel supply systems for newbuild and existing vessels require expert engineering and consultation to ensure the correct components and materials are integrated in compliance with future fuels.

Controlling fuel viscosity and temperature at engine inlets remains crucial. Therefore introducing any new fuel to an existing fuel supply system may require an evaluation of the system and potential modifications to maintain reliability and peak performance. These avoid system instabilities, leaks, clogging, thermal stresses and excessive wear.

Whatever option you choose to be compliant, you can rely on Auramarine's expertise to ensure the safest and most efficient solution available.

READ MORE IN AURAMARINE WHITE PAPERS:

Definitions

Heavy fuel oil (HFO): available either with a high sulphur content (e.g. RMA-RMK), in which case a scrubber is needed, or with a 0.50% (low) sulphur content (also called global fuel), or a 0.10% (ultra low) sulphur emission control area (SECA) compliant content. In both latter cases a scrubber is not needed. HFO needs to be heated to reach the correct viscosity. When using HFO, a fine filter is recommended to prevent potential damage from impurities, such as cat fines.

Liquefied petroleum gas (LPG, LP gas, or condensate), is a flammable mixture of hydrocarbon gases such as propane and butane. (Wikipedia)

Marine diesel oil (MDO): based on today’s availability, MDO (DFB/DMB) is suitable for use by vessels operating in non-SECA areas due to its 0.5% sulphur content. To reach the correct viscosity, it needs to be cooled using a cooler.

Liquefied natural gas (LNG) is natural gas (predominantly methane, CH4, with some mixture of ethane, C2H6) that has been cooled down to liquid form for ease and safety of non-pressurized storage or transport. (Wikipedia)

Marine gas oil (MGO): required for operation in SECA areas and in certain ports. Sulphur content 0.1% (DMA, DMZ). To reach the correct viscosity, a cooler or possibly a chiller is needed. A compatibility check of the feeder and booster pumps is required before switching to MGO to ensure that any viscosity-related issues, and subsequently the risk of capacity and lubrication problems, are avoided.

Biofuels: biomass and waste-derived liquid fuels for large diesel engines (Bioflex project)

Every ship is different from a technical, trading and operational perspective.

However, for all retrofits some elements remain essential, namely cost-efficiency and short lead times from design to delivery.

Auramarine is at your service to help you navigate the complexities of class compliance, and find the safest and most cost-efficient retrofit solution for your fuel supply system.

Contact us to find the best solution to meet your ship’s needs.

+358 20 486 5030 / after.sales@auramarine.com