Auramarine MGO solutions

Aurmarine fuel supply systems are ideal for operators using single-fuel marine gas oil (MGO) or for multi-fuel systems.

The first step towards low-sulphur operations without compromising engine health

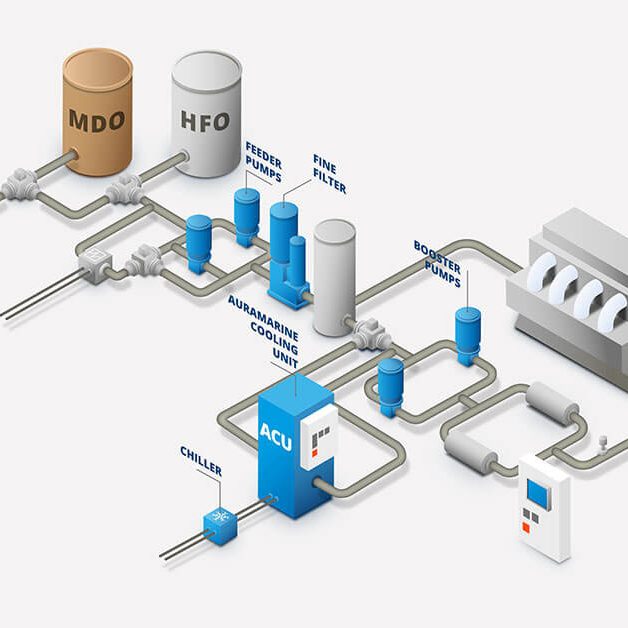

The significantly different properties of heavy fuel oil (HFO) and low-sulphur fuels in multi-fuel systems requires an expert approach. We configure each system to meet a customer’s needs and ensure it has proven long-term reliability and operational performance. Auramarine fuel supply systems are ideal for operators using single-fuel marine gas oil (MGO) or for multi-fuel systems.

In most marine diesel engines, the viscosity of the fuel needs to be at least 2.0 cSt. Heaters are universally used with HFO. Operators, who only use MGO as a fuel, do not usually need heaters and thus we can also supply our marine feeder booster units without heaters. However, when MGO is used, the fuel in the system requires cooling to meet engine viscosity and lubrication requirements.

Auramarine’s controlled cooling solutions include a cooler unit, a chilling unit (when required) and a cooling water circulation unit. Controlled cooling enables the fuel to be cooled to even below 20°C.

Auramarine MGO system's benefits and features:

- Receive turn-key delivery from industry experts.

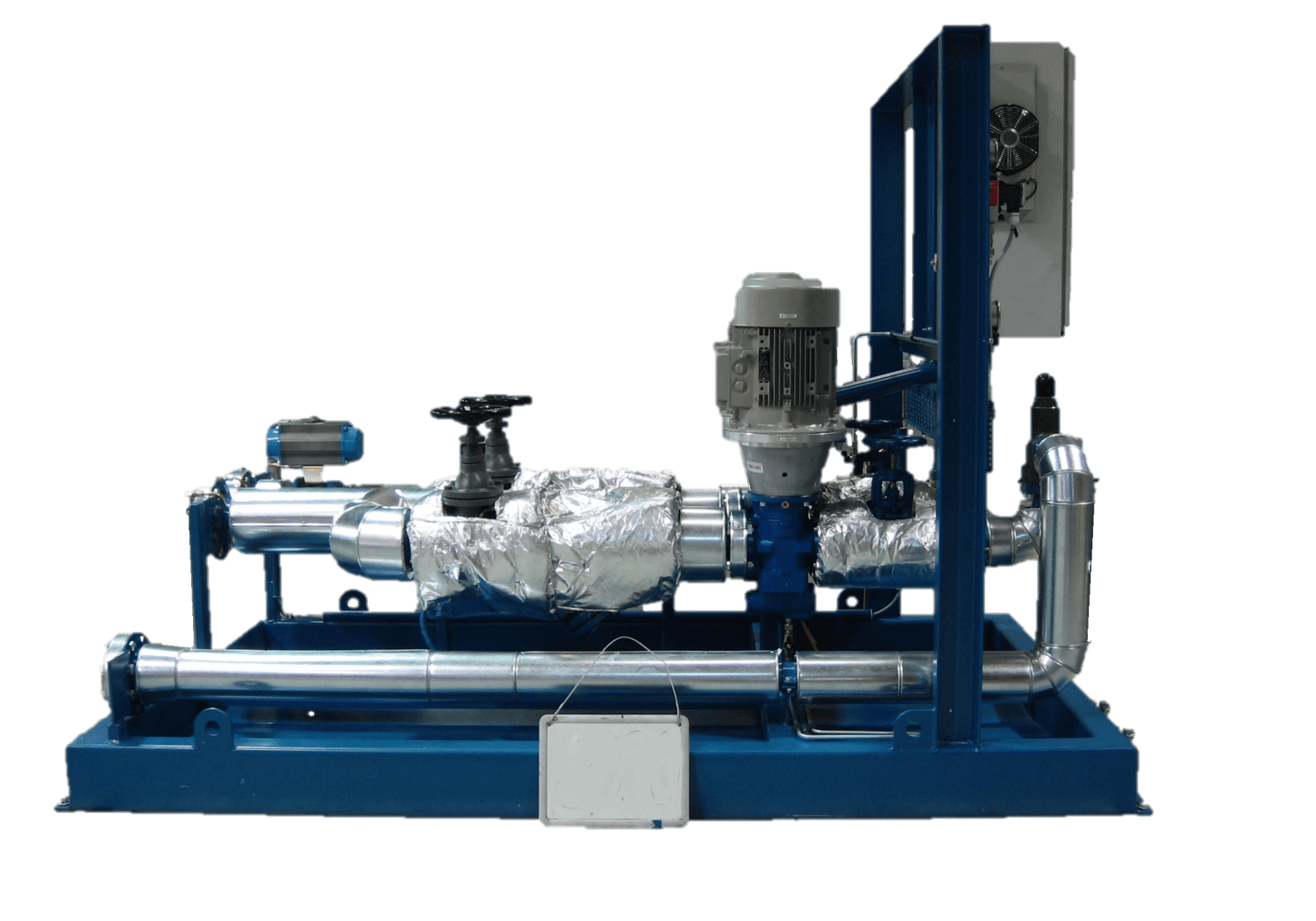

- Enjoy easy and flexible installation either for independent components or for a compact integrated unit.

- Benefit from a high-quality design and components.

- Choose a design option for constrained spaces, allowing the unit to be split into two or three parts for smooth transport and installation.

- Get support for updating the fuel oil system diagram.

- Select from both seawater and LT water configurations.

- Optionally include emergency pump.

Auramarine MGO solution consists of:

MGO systems for retrofits

Auramarine Marine Gas Oil supply solutions enhance operational and environmental efficiency by allowing flexible fuel use. These solutions include MGO Feeder units and various combinations of MGO Feeder and Booster parts, designed to serve both single and multiple engine configurations.

Our MGO units are designed and installed on a retrofit basis. They are ideal for vessels with multi-engine configurations where one conventional booster feeds two or more engines. When an additional MGO unit is installed, different engines can operate on different liquid fuels. This flexibility is especially advantageous for ships with scrubber installations, as it allows for readily changing fuels.

MGO operation typically does not require space-consuming heaters, heavy automatic filters, or thermal insulation, which makes the footprint of the MGO feeder-booster remarkably smaller compared to a conventional HFO supply unit.

Auramarine MGO supply units can be tailored as a feeder part connected to existing booster(s) or a fully independent complete MGO supply unit depending on the engine configuration.

MDO/MGO

For ships without scrubbers

In case of existing ships, your ship may be required to run on fuels that the main and auxiliary engine fuel handling systems were not originally designed for. As a result, certain modifications should be carried out to ensure a reliable, continuous operation.

References

Eco-efficient RO-PAXes Finnsirius and Finncanopus

Finnsirius and Finncanopus, the new ’Superstar’ vessels owned by Finnlines (a part of the Grimaldi group), are eco-efficient ro-paxes and the next step in the evolution of green shipping. They operate between Finland and Sweden.