SOLUTIONS FOR METHANOL OPERATIONS

Auramarine provides complete methanol fuel supply systems for ships, covering methanol transfer from bunkering station to engines, precise flow, pressure and temperature control, safety functions and backup fuel systems. Our modular solutions support both newbuild and retrofit projects, helping shipowners adopt methanol as a marine fuel to reduce emissions and meet tightening regulations.

SECURE YOUR PLACE IN OUR METHANOL WEBINAR 5/3/2026!

In this second webinar 5/3/2026 10:00 EET | Methanol: safe fuel supply solution, we will take a deep dive to methanol and why it is a viable option as a marine fuel and how to build methanol fuel supply solution.

Register here.

METHANOL - A VIABLE OPTION FOR MARINE DECARBONISATION

Methanol is one of the most viable clean marine fuels to cut greenhouse gas emissions and help shipowners meet global decarbonisation and IMO emissions reduction targets. When produced as green methanol, full carbon neutrality can be achieved.

Compared to conventional marine diesel oil, methanol significantly reduces SOx, NOx and particulate emissions, supporting compliance with EEDI/EEXI and CII requirements as well as local emissions regulations in ports and coastal areas.

Thanks to an existing global logistics and regulatory framework, methanol is a practical and scalable alternative fuel for shipping, available today for both newbuilds and retrofits.

METHANOL FUEL SUPPLY SYSTEM WITH COMPLETE AUTOMATION

Auramarine Methanol Fuel Supply System delivers methanol from the bunkering station to the main engines and other methanol consumers on board while continuously regulating flow, pressure and temperature of the methanol. This active control, combined with high‑efficiency filtration, ensures that the system is compatible with most two‑stroke and four‑stroke marine engines and other methanol consumers.

The methanol fuel supply system maintains the required supply pressure within specified tolerances during load changes and complies with strict marine safety requirements. The compact, modular design supports efficient onboard arrangement and can be adapted to the available space in both newbuilds and retrofits.

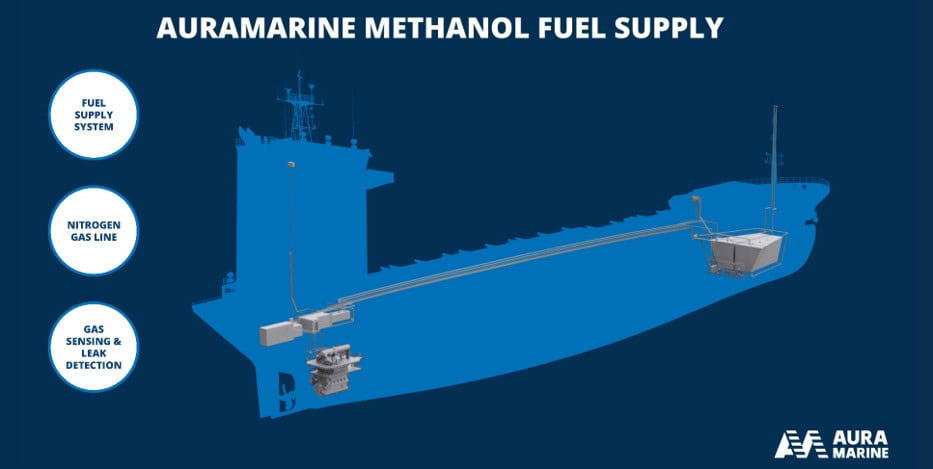

What is included in Auramarine methanol fuel system - look for more details in from the following demo. Click the circles on the left for more details about methanol fuel supply system, nitrogen gas line and gas sensing & leak detection.

AURAMARINE METHANOL FUEL SUPPLY SYSTEM IS INTEGRATED TO VESSEL AUTOMATION

EXAMPLE OF AUTOMATION SYSTEMS ONBOARD:

- Ship automation system

- Engine control system

- Alarm & monitoring system

- Propulsion control system

Auramarine's methanol fuel supply system can be integrated with these and other onboard systems.

EXAMPLE OF AURAMARINE METHANOL FUEL SUPPLY SYSTEM:

- Fuel supply unit (LFSS) and Master fuel valve unit (MFV)

- Gas and leak detection system

- Tank (storage and service) management system

- Bunkering management system

- Double wall pipe monitoring system

- Automation and ESD systems

- Ship-to-shore link system (SSL)

- Inert gas system

EXPLORE AURAMARINE FUEL SUPPLY SYSTEM IN DETAILS

Explore Auramarine’s methanol fuel supply system on the right and see how we can support your transition to methanol-powered operations.

On the demo you can:

- Explore key safety, control and monitoring features

- Understand how the system integrates with engines and onboard automation

- Learn what to consider when planning a methanol project for your fleet

SAFETY FEATURES OF THE METAHNOL FUEL SUPPLY SYSTEM

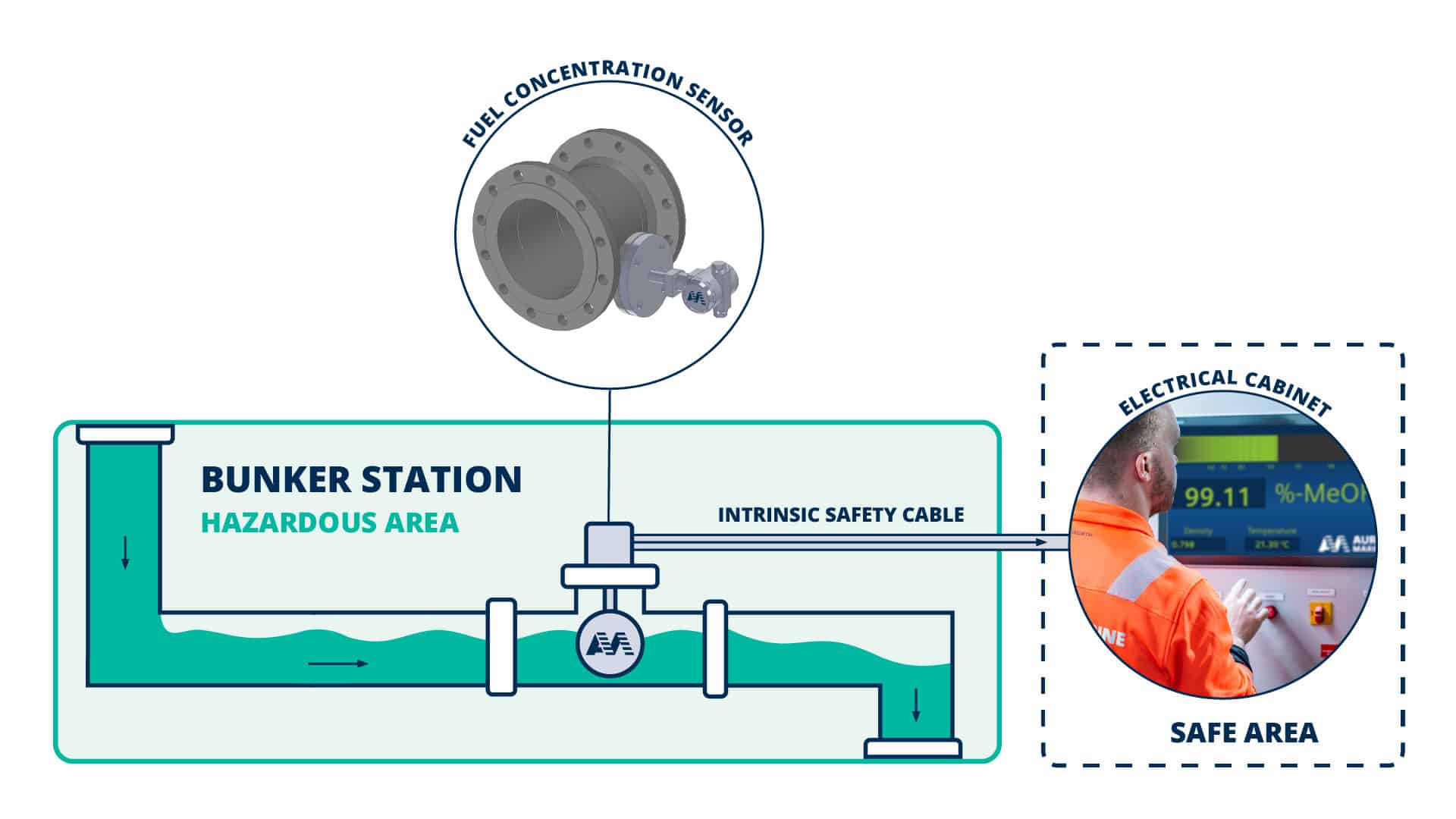

All materials, components and manufacturing procedures in the Auramarine methanol fuel supply system are selected and qualified for methanol service and for the specific marine application. The unit is designed for installation in closed and Ex‑rated hazardous areas, and all applicable IECEx standards and Health and Safety Guidelines (HSE) are taken into account.

A high level of safety is achieved through a self‑draining mechanical design, combined with a nitrogen inerting process and double block‑and‑bleed configurations for all serviceable methanol line segments. All components and electrical equipment are specially selected for safe use in hazardous areas, and electrical cabinets, control panels and variable frequency drives can be installed in a safe area to minimise electrical equipment inside the hazardous zone.

These safety features help shipowners adopt methanol as a marine fuel while managing risk and complying with class and flag‑state requirements.

SEAMLESS BACKUP FUEL SYSTEMS FOR DUAL-FUEL METHANOL OPERATION

For dual‑fuel engines operating on methanol, a reliable backup fuel system is essential. If a disturbance is detected in methanol combustion, the backup fuel system must take over immediately to secure safe and continuous vessel operation.

Auramarine HFO and MGO fuel supply units are designed to maintain engine‑specific fuel temperature and other requirements at all times, making them ideal for backup or pilot fuel use alongside the methanol fuel supply system. These systems are already trusted and proven in current LNG‑operated vessels, providing a solid reference for future methanol‑fuelled ships.

Choosing the methanol fuel supply system, backup fuel system and pilot fuel system from the same supplier offers clear synergies and benefits:

- Streamlined project administration for the shipyard during the shipbuilding phase

- Optimised design for the exact space available

- Consistent documentation and interfaces from a single supplier

- One central contact point for engineering, delivery, commissioning and lifecycle support

AURAMARINE METHANOL FUEL SUPPLY SYSTEM AT TERN VIK

Find here from the video on the right - Auramarine methanol fuel supply system onboard Tern Vik.

On the video, our VP of project sales, Tuomas Häkkinen, tells about our good cooperation with Tern Tank shipping company. This project is a perfect example on how we work best with our customers. The earlier the customer takes us in, the better we can help them - to design and build safe and compliant technical systems for their specific needs.

METHANOL FUEL SUPPLY SYSTEM WHITE PAPER

The purpose of this whitepaper is to look at the key elements of methanol fuel supply system interfaces and the potential challenges of integration, as well as the solutions that can be deployed, including expert design and planning. You will learn more about for example:

- Methanol characteristics

- About methanol fuel supply system

- Integration to ship and engine systems

REFERENCES

TERNTANK TANKERS

For Terntank’s next‑generation chemical and product tankers, Auramarine delivers methanol fuel supply systems that support low‑emission operations and future‑proof fuel flexibility. Terntank's ships are built at China Merchants Jinling Shipyard (Yangzhou), hulls CMYZ0129-CMYZ0131, with the first vessel of the series to be delivered in March 2025.

MEIN SCHIFF 7

Mein Schiff 7 is a state-of-the-art vessel that prioritises sustainability and efficiency. With a length of 316 meters and a width of 35.8 meters, it can accommodate nearly 2,900 passengers and 1,000 crew members. On Mein Schiff 7, Auramarine’s methanol fuel supply solution contributes to the vessel’s sustainability concept by enabling the use of methanol as an alternative marine fuel.

WHAT IS THE ANNUAL COST OF WATER IN METHANOL?

Learn more on how to monitor methanol water content with Auramarine water content analyser.