Fuel Changeover System

Safe and controller fuel changeovers with the push of a button.

safe and controlled fuel changeover

Do you operate in sulphur emission control areas?

If so, you know that the changeover process between high-sulphur content heavy fuel oil (HFO) and low-sulphur content fuels is complex and time-critical. Engine and fuel-system health are dependent on safe, controlled fuel changeovers.

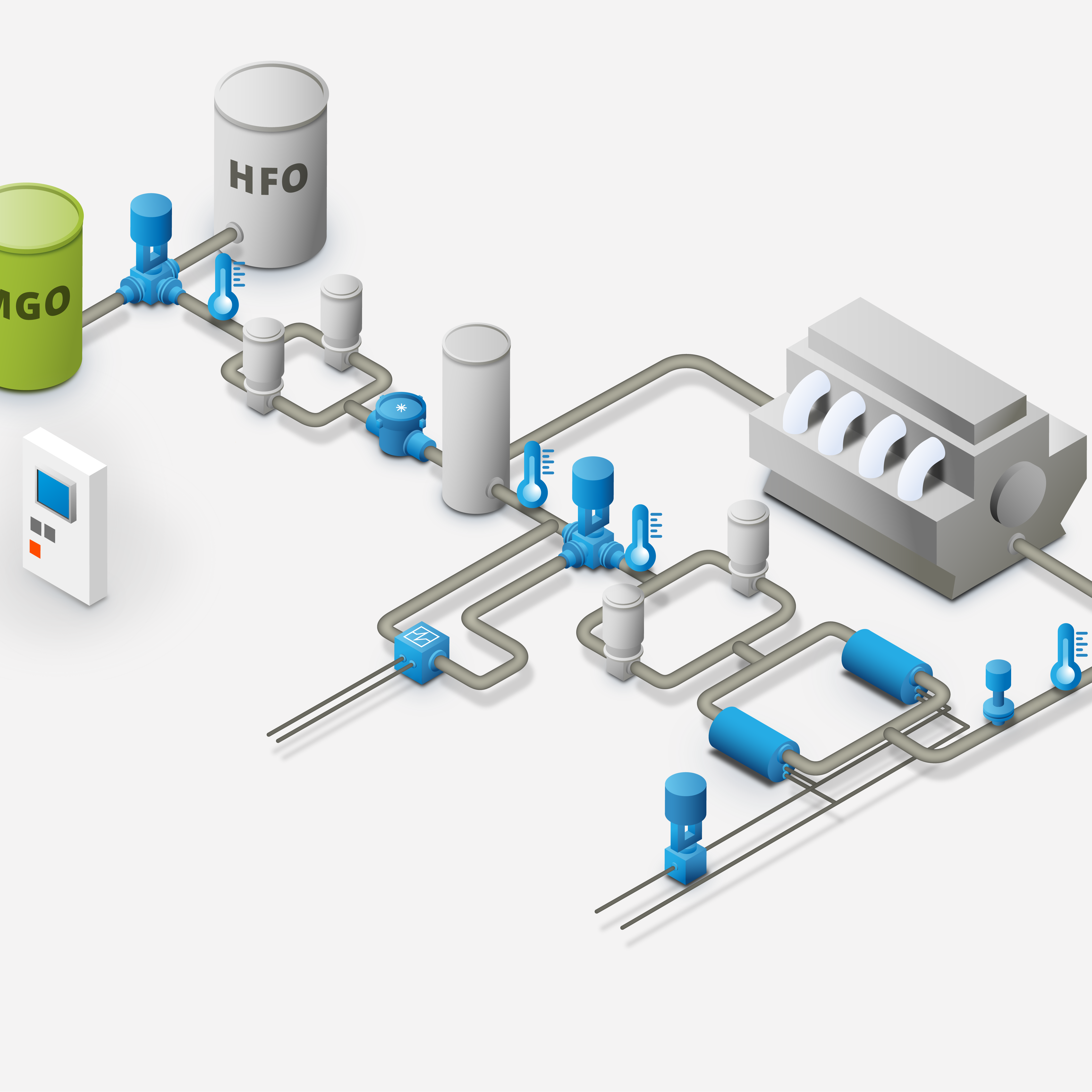

Auramarine’s fuel changeover system offers a cost-efficient, rapid method for enabling a vessel to use different fuel types and comply with sulphur emission control area (SECA) requirements. Changeover is ideal for both newbuilds and retrofits, so if you are thinking of making the switch, we have the solution for you.

Critical control of different fuel properties

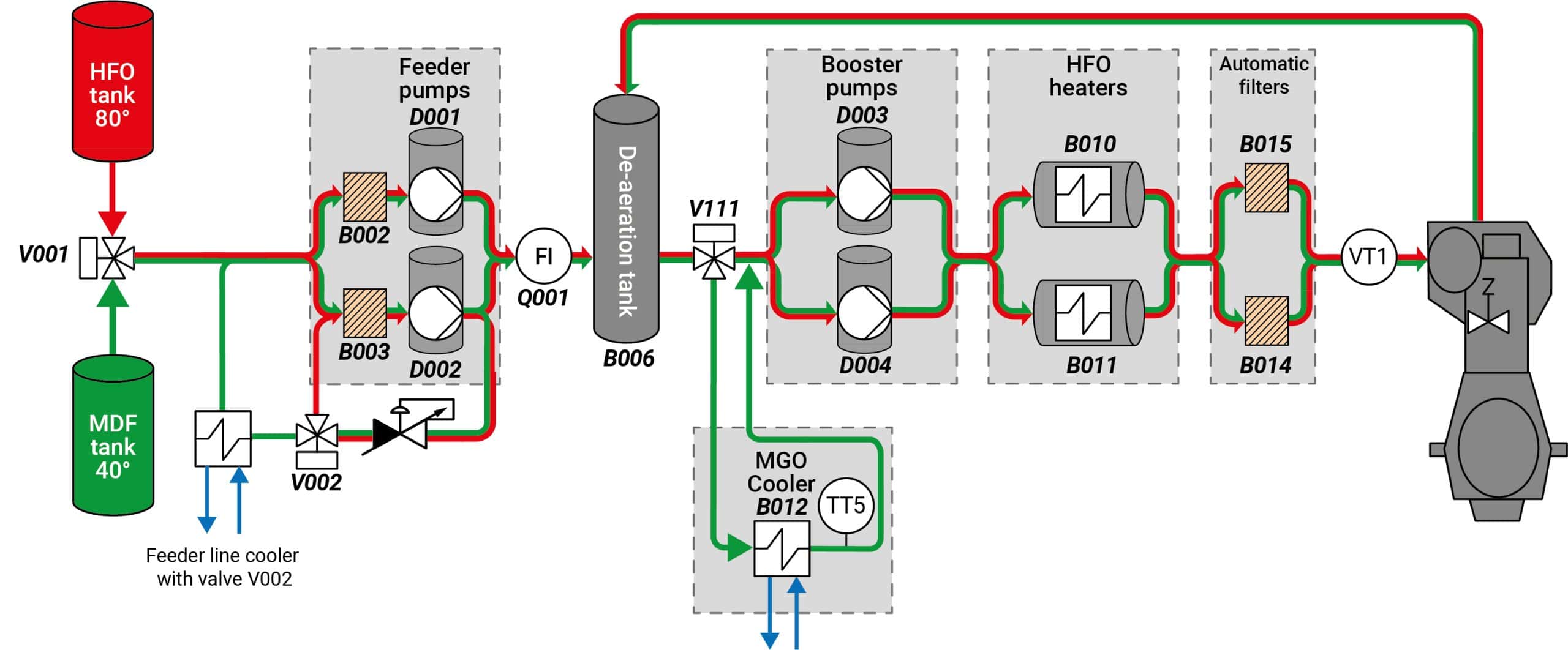

The significantly different properties of HFO and low-sulphur content fuels pose a number of challenges that have to be successfully overcome to achieve a controlled, safe fuel changeover. HFO has a naturally high viscosity, while low-sulphur content marine diesel fuels (MDFs) such as marine gas oil (MGO), ultra-low sulphur fuels (ULSFO), light fuel oil (LFO) or diesel fuel oil (DFO) have a low viscosity.

The key is to manage and stabilise this viscosity by controlling fuel temperature through heating or cooling. Fuel in the system can have an initial temperature difference of up to 100°C. Temperatures have to be equalised, but to protect the system from thermal shock, it is essential to keep the temperature change rate to a maximum of 2°C/minute.

Engine and fuel-system health are dependent on a number of factors including:

- Injection pressure losses caused by too low a viscosity may result in difficulties during start-up and low-load operations.

- Too low a viscosity reduces the effectiveness of the fuel as a lubricant, which can result in fuel pumps sticking and working ineffectively.

- In addition to the engine, other machinery with moving parts in the fuel-circulation system has minimum viscosity requirements. For these parts, a low viscosity can also cause malfunctions due to lubrication issues.

- Interruptions in fuel supply during the changeover process can lead to reduced engine power or in the worst-case scenario, total loss of propulsion, which could be hazardous for the vessel, its crew, passengers and cargo.

The changeover process requires three critical elements:

- The viscosity must not drop below 2cSt.

- The viscosity must not exceed the engine's maximum limits.

- Temperature change rate at the engine inlet must not exceed 2°C/minute.

Easy and safe to operate

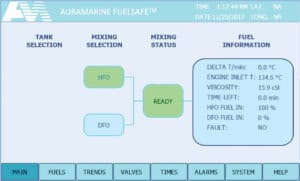

The changeover process is controlled from a touch screen. All steps are automatically controlled using continuous viscosity and temperature sensor feedback. There is no need for a vessel to reduce its speed during the fuel changeover process. It is suitable for various engine loads, fuel consumption rates and fuel system volumes.

Your delivery

Changeover system is delivered as part of a complete fuel supply system.

A standard delivery comprises:

- A fuel selector control panel with 7” touchscreen, mounted on a control cabinet door or supplied as an individual component

- Temperature sensors for feedback processes

- Main changeover valves; the number of valves and their sizes are project-specific and defined according to customer needs

- Feeder line cooler

- A cooler (with capacity control)

For additional cooling needs, Auramarine modular chillers (AMC) are available.

Installation services, fuel system diagram updates, commissioning and turn-key packages are all available and support the easy integration of changeover system into your fuel supply system.