Auramarine ammonia fuel system

Ammonia is a very promising marine fuel alternative due its potential of being a net zero fuel - when produced sustainably. Auramarine Ammonia fuel supply systems enable our customers meet their decarbonisation targets.

Why ammonia?

Auramarine has over 50 years of experience in delivering fuel supply systems for a variety of different fuels. These fuels include marine fuel oils (distillates and heavy residuals), natural gas, biofuels and methanol. The latest addition to our wide range of fuel supply systems caters to Ammonia. Interest in ammonia operated systems is growing, which is why we have developed our offering, the Auramarine ammonia fuel supply system accordingly and are now ready to offer our state-or-the-art fuel supply systems for ammonia operated ships as well.

Auramarine ammonia fuel supply system is tailored to fit our customers' specific needs

Our primary focus is to deliver a safe, reliable and high quality fuel supply system to vessels fueled by ammonia.

The scope of our delivery is tailored to fit our customers’ specific needs however, as with our methanol systems, we are capable of providing holistic solutions that cover a comprehensive scope of delivery.

Auramarine’s ammonia fuel supply system is suitable for both two-stroke and four-stroke engines as well as other consumers. All safety, design and material requirements are strictly followed. Dedicated designs are available for both high-and low-pressure arrangements.

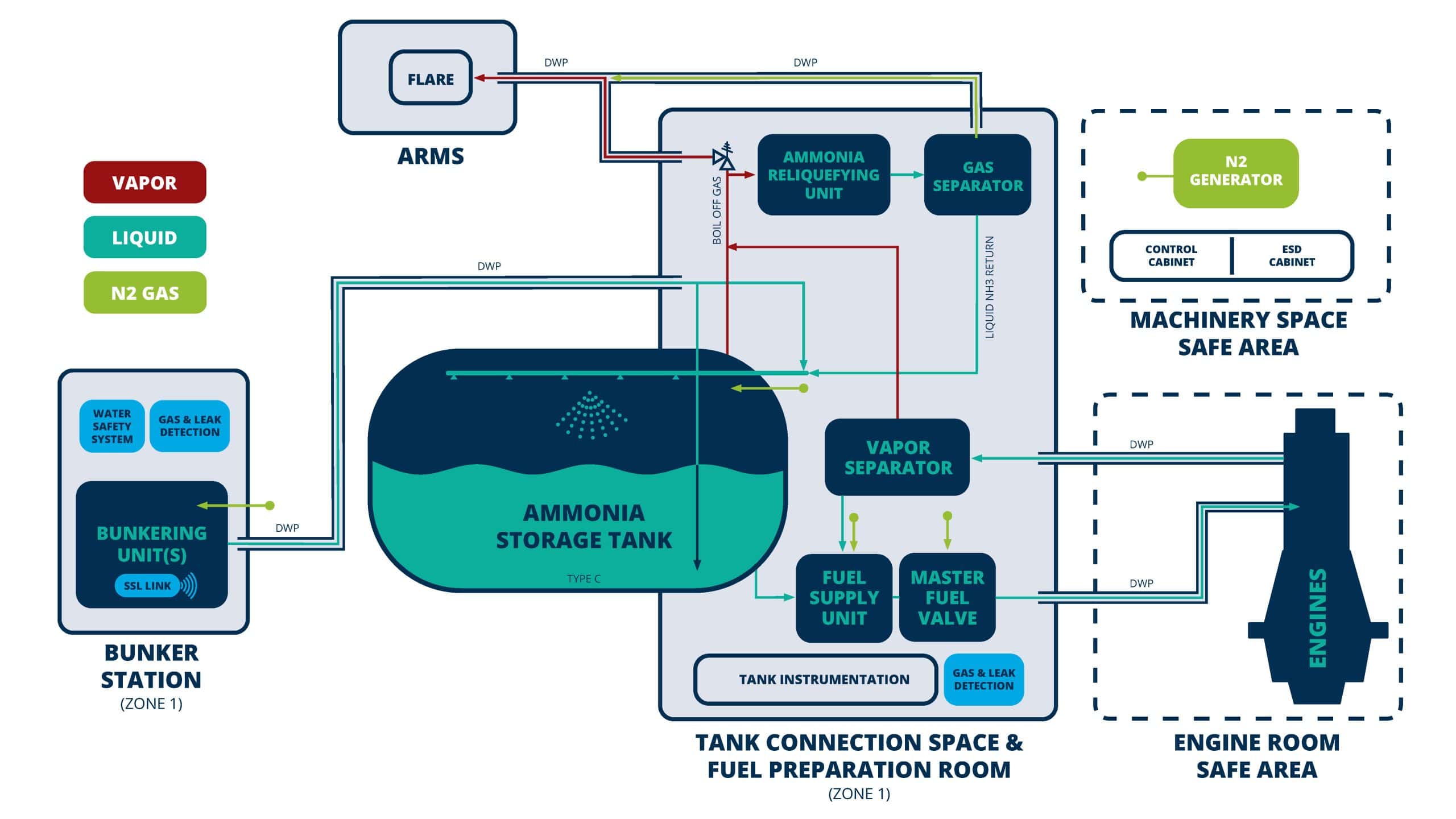

Ammonia system scope

Auramarine’s most comprehensive scope includes all necessary equipment from bunkering through to fuel delivery for onboard fuel consumers. Full scope includes bunkering units, fuel supply units, master fuel valve manifold, reliquefying system, ammonia mitigation system (ARMS), gas and leak detection, bunkering water safety system, ammonia control and safety system, nitrogen generation system, as well as tank design. Features of some main components are presented next.

Functions and safety features

Bunkering station

- Leak detection, water safety system and a ship-to-shore link.

Auramarine tank design

- Design for tank connection space (TCS) to C-type tanks.

- Integration allows for compact installation.

Ammonia fuel supply unit

- Actively regulates and maintains the correct fuel pressure and temperature.

- Measures fuel consumption.

- Filters impurities from liquid ammonia that could damage the consumer.

Master fuel valve manifold

- Allows for isolating and nitrogen purging of one or several consumer(s) from the system by utilizing double block-and-bleed arrangements.

Nitrogen generator

- For purging & inerting of the ammonia system.

Vapour & gas separators

- Separates ammonia vapour from liquid ammonia, where needed.

- Extraction of nitrogen and other trace gases from the ammonia system.

Ammonia reliquefying unit

- Reliquefies boil-off gases from the ammonia storage tank and other vapour sources.

Ammonia release mitigation system (ARMS)

- Featuring controlled combustion, capable of handling ammonia release from the system.

- Ammonia content measurement.

Ammonia gas detection system

- Detects possible gaseous leaks.

- Ammonia fire detectors as optional offering.

Automation system

- Control of fuel supply unit and master fuel valve manifold functions.

- Automatic purging of block-and-bleed valves.

- ESD functions.

Pilot fuel supply & bio-diesel backup system

- Auramarine can offer pilot fuel supply system and fuel supply system for the ships first fuel (e.g. bio-diesel).

Ammonia in shipping - Auramarine white paper

Contact us

Would you like to hear more about Auramarine solutions? Please do not hesitate to contact our sales.